Airgun

Find all our latest updates, advice and guidance relating to airgun ammunition for use in live quarry and target shooting.

Get information on the legal shooting season for mammals and birds in the UK.

Apply for funding for your project or make a donation today

Comprehensive information and advice from our specialist firearms team.

Everything you need to know about shotgun, rifle and airgun ammunition.

Find our up-to-date information, advice and links to government resources.

Everything you need to know on firearms law and licensing.

All the latest news and advice on general licences and how they affect you.

Home » Sustainable ammunition » Using non-lead shot for live quarry shooting

Following the statement issued by the game shooting and other rural associations (BASC, British Game Alliance, CLA, Countryside Alliance, GWCT, the Moorland Association, NGO, Scottish Land and Estates and SACS) calling on members to engage with a phased transition over five years to using non-lead shot for taking live quarry, this BASC guide provides information for determining what non-lead cartridge is suitable for you.

There remains some scepticism of the effectiveness of non-lead shot, despite the fact that field trials comparing lead and steel shot have found no difference in the number of birds killed per shot.

In Denmark, the Netherlands and Flanders, where the use of lead shot is illegal, those who shoot report no problems with effectiveness. In these areas more than 95% of those who shoot use steel shot, and that is likely to be the most popular alternative in the UK.

It is worth bearing in mind that wildfowlers in the UK have been using non-lead cartridges for more than twenty years and that British pigeon shooters have increasingly used steel as the price paid per bird has increased for those taken with non-lead shot.

The development of biodegradable wads for steel shot is a real game changer for the future use of steel cartridges.

The use of non-lead shot removes the argument that game shooting uses a toxic material, banned in many other applications, to the detriment of animal welfare, the environment and human health. Game harvested with non-lead shot will not come with a Food Standards Agency (FSA) warning, meaning it can be enjoyed by children and pregnant women and can be eaten more frequently by everyone.

This BASC guide sets out the steps you need to take to use non-lead shot. If you are in any doubt about which ammunition can be used in your gun consult a reputable gunsmith.

BASC is working to ensure that shooting is not damaged by the transition to non-lead shot.

As members of FACE, the European association of hunting organisations, BASC is working to ensure that any EU regulations to restrict lead shot are appropriate, reasonable and easily complied with.

A member of BASC staff chairs FACE’s ammunition working group.

In the UK we are keeping the government, MPs, and other legislative assemblies informed and have held meetings in Westminster and Whitehall to brief the key people.

We are working with the cartridge manufacturers and proof houses. We are issuing advice on how to transition and will be working the necessary elements into our training programme.

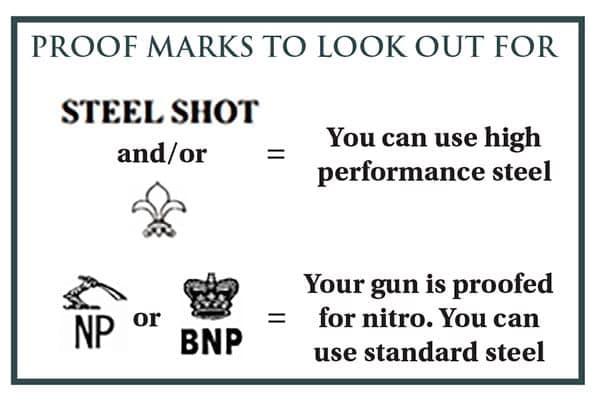

1. Determine what type of steel shot you can use in your shotgun. Check the proof marks on your barrels.

2. High performance steel shot cartridges should be marked as such on the box and on the cartridge.

The shot size (pellets) will most likely be larger than number 4 (3.1mm) and the load heavier than 32g. Small shot high performance steel cartridges are likely to be produced in the future so checking the markings on the box and the cartridge is a positive habit to adopt before shooting. What chokes you can use depends on the size of the shot and if you use multi chokes.

You can check with a gunsmith if your chokes are suitable. If in doubt do not use any more than half choke. For 10 and 12 bores you should not use shot larger than BB in a choke tighter than half. For 16 and 20 bore you should not use shot of size 3 or larger in choke tighter than a half.

3. Standard steel shot will be smaller in shot size (pellets) than British number 3 (3.25mm) and may be used through any choke. For traditional light weight game guns the British Proof Authorities recommend no more than a quarter choke.

4. When choosing a steel shot cartridge, you should increase the shot size by at least two sizes. If you normally use lead no 6 shot (2.6mm), you should go up to steel no 4 (3.1mm). The tighter patterns of steel shot will compensate for the loss in total numbers of shot and so there is no need to increase load weight.

5. Steel shot patterns tighter than lead. Steel shot through a half choke patterns more like lead shot through a full choke. Consider opening up the choke you use. Have a session on a pattern plate to see how steel shot patterns in your gun and choke combination.

You may find that when you fire steel through a choke greater than half the pattern begins to widen again – but you won’t know without a visit to a pattern plate. If your gun has fixed chokes they can be opened up by a gunsmith. You should consider having your gun re-proofed after this is done.

6. Practice on clays. Studies in the field have found that those who shoot cannot tell if they are using steel or lead shot. When changing cartridges you should always pattern your gun / cartridge combination and practice on clay targets. This will help you get the best out of steel cartridges when you shoot live quarry.

Using Bismuth and Tungsten Matrix

1. Bismuth is as soft as lead but less dense. You should increase the shot size by at least one from the size you use in lead. For example; if you use lead size 5 (2.8mm) you should increase to at least size 4 (3.1mm).

2. Tungsten varieties come in many forms. It tends to be as dense or denser than lead so you may not need to change the shot size or you might even reduce the size of the load.

The market for non-lead shot is developing rapidly and the cost is likely to fall as demand and production increases.

The development of biodegradable and other non-plastic wads/cups for steel cartridges makes it possible to shoot steel without littering the countryside with single-use plastics.

The cost of steel is comparable to or less than lead. Bismuth and tungsten varieties are considerably more expensive than lead and steel. There is a wide choice of non-lead shot available for 10, 12 and 20 bore guns. The range for 16, 28 and .410 bores are more limited but expected to improve.

Contact us via email for more advice and guidance: lead@basc.org.uk

Find all our latest updates, advice and guidance relating to airgun ammunition for use in live quarry and target shooting.

Everything you need to know as we move away from lead shot and into a phased transition to lead free ammunition.

Here you’ll find all our latest updates, advice and guidance relating to large and small calibre rife ammunition for use in live quarry and target shooting.