Lead ammunition restrictions – your questions answered

Read our answers to frequently asked questions about the planned lead ammunition legislation and what it means for shotgun, rifle and airgun shooters.

Get information on the legal shooting season for mammals and birds in the UK.

Apply for funding for your project or make a donation today

Comprehensive information and advice from our specialist firearms team.

Everything you need to know about shotgun, rifle and airgun ammunition.

Find our up-to-date information, advice and links to government resources.

Everything you need to know on firearms law and licensing.

All the latest news and advice on general licences and how they affect you.

BSA has recently launched two new spring-powered air rifles – and they are being made in the UK. Mike Montgomery reports from the company’s Birmingham factory.

Do you remember the first proper gun you got to shoot? For me it was a BSA Comet air rifle which belonged to my older brother, and, in an uncharacteristic display of generosity, he let the 11-year-old me have go with it, plinking in our back garden.

I’ll wager many readers of this will have similar memories of their first steps into the world of shooting. The break-barrel springer was ideal for youngsters. Cheap and sturdy, and all you needed was a pocketful of pellets and arms strong enough to compress the spring and cock the trigger.

Even though they have largely been superseded by modern PCP airguns, spring-powered air rifles have never gone away, and I was delighted to hear that BASC airgun partner BSA has introduced two new models and is making them at their factory in Birmingham.

The cheaper (RRP £229) Comet SE is an improved version of a model formerly made in Spain by Gamo. Gamo, Europe’s largest manufacturer of airguns, took over BSA Guns in the 1980s, and manufacturing was subsequently divided between the two firms, with the springers being made in Spain and the PCPs in England; now both brands are owned by an American private equity group, BRS. The Comet is a no-frills rifle but very well made, with a synthetic stock, and therefore lighter – an ideal first gun for junior shooters.

The Meteor Super takes things up a notch or two, although keeping within a very affordable price range (RRP £299). It has a stylish, Italian-crafted beech stock and some innovative improvements all designed in-house at BSA, including an all-new cylinder, new trigger unit and improved cocking link. So, well in keeping with the long and noble tradition of BSA airguns, just adding that extra refinement while maintaining a highly competitive price point.

Earlier this autumn, I visited the BSA factory at the end of Armoury Road in Birmingham’s Gun Quarter to meet sales and marketing director Jon Hatton.

He explained that the Birmingham base makes all BSA and Gamo PCP guns, except for one entry level Gamo model, but he was delighted that BSA springer guns were now being made there, too.

“It’s a bit of a coup for us,” he said. “We wanted to show we could still make break-barrel guns in the UK. And it’s a way of testing the market to see if we can sell more guns here because they are British made. Fundamentally, BSA is the premium brand in the partnership. Both brands make guns with similar capabilities, but the BSA models carry more refinement and additional features, such as walnut or laminate stocks, shrouded barrels and a more premium finish.

“Our stocks are supplied by Minelli in Italy, but they are just about the only part of the guns that are sourced from abroad. Everything else is either made here in Birmingham or bought from select UK component suppliers.”

Production of the new spring-powered air rifles started at the beginning of 2023, and they were introduced to the public at the British Shooting Show in February. The reception has been very positive, with favourable reviews of both guns by Dave Barham in the February issue of Airgun World magazine.

Despite the tough competition at this end of the market, from airgun makers in Turkey, China, Germany and the UK, Jon confirmed both spring-powered air rifles were selling well through their network of 400 plus UK dealers and many more in 72 other countries.

“There’s a lot of love for BSA out there,” he said. “BSA guns have a very good reputation, and we are particularly renowned for the production and accuracy of our barrels. I always say, any gun is only as good as its barrel, and the shooter aiming it, of course.”

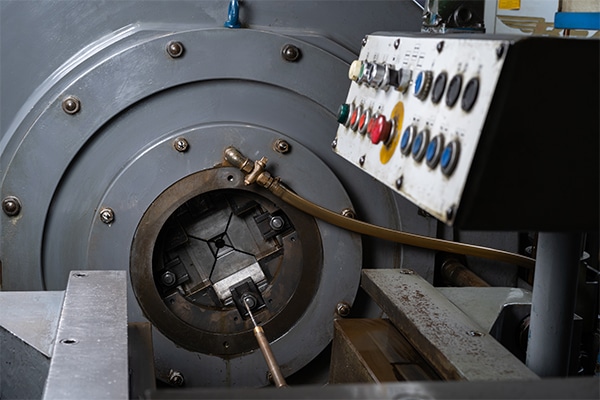

All BSA airgun barrels are cold hammer forged in the workshops at Armoury Road. Jon took me round to see the process in action. Machine shop manager Mark Walker explained how each barrel starts off as a length of steel bar, which is then cut to size and drilled to create the bore.

The next stage is where the magic happens. The barrel is placed in a cold hammer forger which pushes a mandrel with the rifling elements slowly through the bore, with a slight rotation, while a computer-controlled array of hammers strike the barrel all over, applying 30,000 blows in a nine-minute process, compressing the metal around the mandrel as it passes along the bore. The result is a slightly smaller barrel diameter and a precision-formed rifling twist.

Next the barrels are tested for trueness, before going on to be finished with the breech seal and threaded muzzle fitting machined at either end, after which they undergo the blacking process. Vats of hot chemical solutions bubble away – they look antiquated and infernal, but next to them are some brand new tanks just ordered and ready to be commissioned once they have been properly tested.

Oh – and I nearly forgot, each barrel is stamped with the proud legend: BSA Guns – made in Birmingham, England.

The barrels are then sent to be made up into finished guns, with the stock, action, trigger and air cylinder all assembled by hand.

Finally, each finished spring-powered air rifle is tested for accuracy by being clamped in a vice and fired down a tunnel to ensure it can achieve a 1/2 -inch group of ten shots at 25 yards.

Every part of the manufacturing process is separate, so production can be switched easily from model to model to meet changing demand, such as when BSA gets a bulk order from the combined cadet forces for its Scorpion light PCP.

“We are very proud to have won that contract ten years ago,” said Jon. “After extensive testing of a number of rifles by the forces, the Scorpion came out top, and the second and third placed rifles were also BSA and Gamo models.”

With its supreme accuracy, lightweight and durable synthetic stock, easy handling and bolt action loading, the Scorpion spring-powered air rifle is ideal for training youngsters that may need to use military rifles in the armed forces.

Jon also filled me in on the fascinating history of the BSA factory. Founded in 1861 from a small union of gunsmiths, Birmingham Small Arms produced millions of firearms and munitions, both for the military and civilian use. The company’s contribution to Britain’s efforts in two world wars was outstanding.

Operating at its peak from premises that occupied a 32-acre site running almost the whole length of Armoury Road, BSA was making Lee Enfield rifles at a rate of 10,000 a week during WWI. During WWII, the factory manufactured more than half of all the small arms used by British forces, including 568,100 Browning machine guns, 1,250,000 Lee Enfield rifles and 60,000 ‘BESA’ machine guns. During 1940, the factory was attacked three times in three months by the Luftwaffe; the bombing destroying 4.5 acres, killing 53 workers and injuring 89.

Air rifle production began in 1905 with the first Lincoln Jeffries model. BSA needed a product to fill the manufacturing void left after the end of the Boer Wars, and air rifles were very successful until production was switched back to military firearms in the war years. After WWII, the company launched its iconic Cadet air rifle, thus beginning a new market which rapidly expanded, spawning many of the famous names we still know and admire today.

Of course, the BSA conglomerate was also famous for making cycles, motorcycles (at one time it was the largest maker of motorcycles in the UK) and even cars, but all these works ceased in the last century, due to various commercial factors, and now all that remains on a much smaller site on Armoury Road is BSA Guns.

However, although the company ceased making cartridge rifles and shotguns 15 years ago, BSA Guns is in good shape, and making tens of thousands of airguns each year for the home and export market. For the past decade BSA has been BASC’s airgun partner and sponsor.

“We are really proud of our association with BASC,” said Jon. “We supply all the guns used on your game fair ranges and airgun courses. BSA very much sees BASC as the governing body for shooting, embodying an ethos of education, safety and enjoyment.”

Read our answers to frequently asked questions about the planned lead ammunition legislation and what it means for shotgun, rifle and airgun shooters.

Campaign against airgun restrictions launched by BASC as Home Office push forward with firearms safety consultation.

Mat Manning explains how airgun shooters can use NV optics to boost their nocturnal pest control, and flags up some of the common obstacles.

Sign up to our weekly newsletter and get all the latest updates straight to your inbox.

© 2025 British Association for Shooting and Conservation. Registered Office: Marford Mill, Rossett, Wrexham, LL12 0HL – Registered Society No: 28488R. BASC is a trading name of the British Association for Shooting and Conservation Limited which is authorised and regulated by the Financial Conduct Authority (FCA) under firm reference number 311937.

BASC Direct Ltd is an Introducer Appointed Representative of Agria Pet Insurance Ltd who administer the insurance and is authorised and regulated by the Financial Conduct Authority, Financial Services Register Number 496160. Agria Pet Insurance is registered and incorporated in England and Wales with registered number 04258783. Registered office: First Floor, Blue Leanie, Walton Street, Aylesbury, Buckinghamshire, HP21 7QW. Agria insurance policies are underwritten by Agria Försäkring.

If you have any questions or complaints about your BASC membership insurance cover, please email us. More information about resolving complaints can be found on the FCA website or on the EU ODR platform.